What Is an 8130 Certificate?

The aircraft parts and maintenance industry must closely follow Federal Aviation Administration standards. In some cases, manufacturers must obtain an official airworthiness approval tag known as form 8130-3. While most in the industry are familiar with the FAA 8130 form and the fact that it is necessary for various export and maintenance, repair and overhaul processes, many are unaware of what this official document does and when to use it. This article provides an in-depth overview of the 8130 certificate, including what it is and how to get one.

Table of Contents

- What Is an FAA Form 8130?

- 8130 Form Terms and Definitions

- What Is an 8130-3 Used For?

- What Can’t an 8130 Form Be Used For?

- FAA 8130-3 Form vs. EASA Form 1

- How to Get an 8130 Aviation Certificate

- Who Is Authorized to Distribute an FAA 8130 Form?

- How Do You Fill out an 8130-3 Form?

- What Are the Different Parts of an 8130 Certificate?

- FAA 8130-3 Requirements

- What Is the Difference Between CoC and 8130-3?

- Repair Services From HRD Aero Systems

What Is an FAA Form 8130-3?

The 8130-3 form, or 8130 tag, is an FAA-required document primarily used to verify parts and components within the global aviation system. Under the FAA Code of Federal Regulations, the 8130-3 form is a required airworthiness approval tag, certifying that an aircraft part is in good enough condition to operate safely within the U.S. and its global partners.

Within this scope, the 8130 serves two primary purposes:

- To approve or certify that new and used parts meet conformity requirements for airworthiness.

- To approve or certify that parts may return to service following maintenance.

The form works differently for these two purposes, so you must understand these uses in detail.

8130 Form Terms and Definitions

You may hear several unfamiliar terms when working with an 8130-3 form. These include product classes and descriptions, as defined by 14 CFR Part 21.321, which have remained unchanged since March 1979. Let’s break down these terms in more detail.

- Class I product: A Class I product is a complete aircraft, aircraft engine or propeller. To meet Class I requirements, the product type must be certified under applicable FAA or international civil aviation authority regulations.

- Class II product: A Class II product is a critical component of a Class I product that would jeopardize the Class I product’s safety if it failed. Examples include wings, landing gears, power transmissions, controls and other critical systems.

- Class III product: A Class III product is any part that is not a Class I or Class II product, such as all standard aircraft components and safety and survival equipment like fire safety and oxygen systems.

- Newly overhauled: “Newly overhauled” is a term used to describe a product that has not been operated since it was overhauled and approved for return to service, with the exception of applicable functional testing during the inspection process.

Originally, the FAA 8130 form was only for exporting Class II and III new and newly overhauled products. However, the FAA updates it regularly to accommodate return-to-service purposes and amended standards. The FAA keeps a current Frequently Asked Questions document that covers 8130 answers, including recent changes.

What Is an 8130-3 Used For?

According to the FAA, the 8130 form only applies to products within the agency’s jurisdiction, improving the identification and traceability of aviation products across the global system. The form serves the following purposes within this scope.

- New products: The form may serve as a statement from the FAA that a new Class I or Class II product conforms to its design and is safe for operation.

- Newly overhauled parts: The form may certify a newly overhauled product’s approval for return to service.

- International use: A manufacturer may use the FAA 8130-3 form when exporting a new or newly overhauled product or shipping a prototype to another country that has a bilateral agreement with the United States.

What Can’t an 8130 Form Be Used For?

While the 8130 form serves multiple purposes, it also has limitations in specific circumstances and functions. The FAA outlines some common examples of how not to use the form.

- Administrative purposes: The FAA Form 8130-3 is not for administrative purposes between two parties, including as a delivery or shipping document.

- Aircraft release: The FAA Form 8130-3 only applies to aircraft parts and is not an aircraft release form.

- Installation approval: The 8130 form only serves as a confirmation of a part’s airworthiness — it does not function as an approval to install a product on a particular aircraft or aircraft part.

Additionally, there are multiple guidelines for how to fill out an 8130 form. For example, only FAA-authorized organizations can issue this tag. While the form can apply to multiple products, it cannot approve a mixture of production- and maintenance-released products.

FAA 8130-3 Form vs. EASA Form 1

Countries must make regulatory agreements for the global aviation system to function smoothly and maintain essential standards. One such example is the EU and U.S. bilateral agreement, which states that products exported or imported to either entity must have a dual release form for domestic and international use. This applies to FAA Form 8130-3 and the EU equivalent, the European Union Aviation Safety Agency Form 1.

The EASA Form 1 serves the same functions as the 8130 form within European Union countries, which is fully intentional — the FAA and the EASA began efforts to homogenize aviation regulations in the late 2000s and worked in the early 2010s on new versions of the form that would function harmoniously. The result was a new version of the 8130 form published in 2014 that closely resembled the EASA form.

The FAA Form 8130-3 comes in single-release and dual-release versions. The single-release form is for domestic use only. The dual release is essential for meeting FAA and EASA requirements when both agencies assess and approve the part in question. To use the form for dual release, the form must be marked appropriately and contain a statement regarding its utility as a dual release. This is required in the following circumstances:

- Exporting aircraft parts for use in the EU

- Sending a part to an EASA repair station within the U.S.

- Returning a part to service for use in an EU-registered aircraft

Users who need a dual release must specifically request one from an approved issuer. For the past few decades, the standard has been to complete all 8130 forms as dual releases. However, all FAA Part 145 Repair Stations must now default to single-release forms unless the user provides a written request for a dual release.

How to Get an 8130 Aviation Certificate

To get an 8130 certificate, the user must request it from the production approval holder or repair service from which they are receiving their parts. The service must then use the appropriate channels for receiving the 8130 certificate before the product leaves its quality control system. They can send a copy of the form to the requestor while keeping a copy on file for their records. Upon receipt, the user must then verify the information on the 8130 certificate, including its correctness and the validity of any signatures.

A user may request a new or updated copy of their 8130 certificate under the following circumstances.

- Loss of form: If the user loses their original 8130 form, they may request a new copy from the originator. The originator may honor this request any number of times with no restrictions.

- Correction request: If the user receives a form with an error, they may request a corrected version from the originating service. The request must be in writing and must identify the errors on the original form. The originating service can then honor the correction request without recertification of the product. In these cases, the corrected form must include a statement in Box 12 stating the nature of the correction and clarifying that the new form does not verify the current status of the part in question.

In some circumstances, a PAH or FAA repair station may not issue an 8130 form. An 8130 form is not necessary for domestic shipments, though it is recommended. Therefore, some services may not offer them unless specifically requested. Additionally, users must request 8130 forms before a part leaves the service’s quality control system — the service facililty cannot issue the form after the product has left.

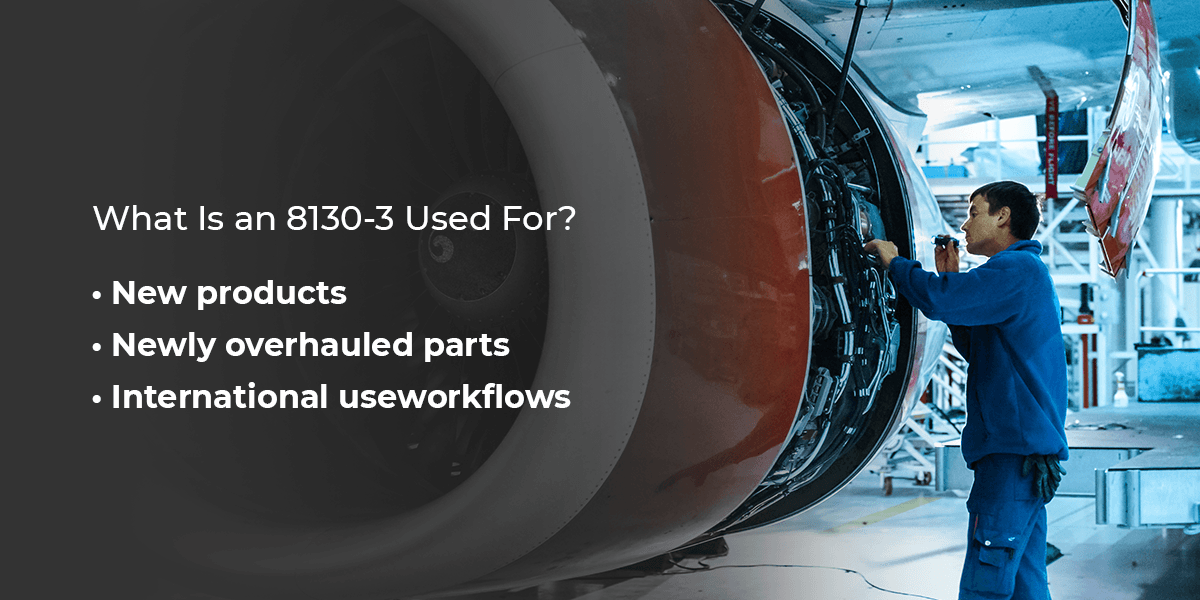

Who Is Authorized to Distribute an FAA 8130 Form?

Under the rules outlined by the FAA in FAA Order 8130.21, Procedures for Completion and Use of the Authorized Release Certificate, FAA Form 8130-3, Airworthiness Approval Tag, the following entities may issue an 8130 form.

- ASI: An FAA aviation safety inspector can sign an 8130 form as a certificate of airworthiness or conformity certification.

- DMIR: A designated manufacturing inspection representative can issue FAA 8130 forms for domestic or export parts.

- DAR-F: Designated airworthiness representatives for manufacturing may issue the form for domestic shipments.

- ODA: Some organizations may have an organization designation authorization unit, which can issue the form for products the organization produces. The ODA unit must inspect the product after it has gone through the producer’s quality assurance program, at which point the ODA unit determines the product’s compliance with CFR requirements.

- Air carrier: Appropriately certified air agencies and air carriers with approved airworthiness maintenance programs can issue the 8130 certificates for approval to return to service.

- PAH: A PAH can issue the form for approval to return to service for domestic products, though this purpose is optional.

If you need the 8130 form from a part manufacturer or repair service, contact them to learn more about how they complete and issue this paperwork.

How Do You Fill out an 8130-3 Form?

FAA personnel and other authorized parties will complete the 8130-3 form. The 8130 completion process is extremely detailed — it changes depending on whether a part is for domestic use, international use or recently overhauled products. Authorized parties must understand all FAA form 8130-3 instructions to inspect and approve everything correctly. You will not distribute or complete the 8130 form unless you are an authorized party. This process keeps everyone accountable and ensures products are safe and FAA-approved before use.

What Are the Different Parts of an 8130 Certificate?

The 8130 certificate has several boxes containing essential information regarding the assessed parts. Boxes 1 through 5 have prefilled or predetermined information regarding the form and the requesting organization, while the remaining boxes pertain to the items assessed.

- Box 6 — Item: This box contains one or more numbers identifying the product, batch or group of items addressed with this form. If the number of items overflows the box, an attached addendum may include the full list, along with identification information as required for Boxes 7 through 11.

- Box 7 — Description: This field requires a descriptive product name for each item covered under the form.

- Box 8 — Part Number: This field requires the part or model number for each item addressed on the form.

- Box 9 — Quantity: This box identifies the quantity of each item listed in Box 6.

- Box 10 — Serial Number: If the product has a serial number, that information goes here. The person filling out the form can enter “N/A” if no serial number is available or if CFR requirements do not ask for one.

- Box 11 — Status/Work: This section has product descriptions using one of four terms. New products produced in compliance with approved designs are “new.” New products that do not conform to standard designs receive the term “prototype.” For any repaired parts, the descriptor would be “repaired” or “overhauled,” as appropriate.

- Box 12 — Remarks: The remarks section is the largest field on the form and includes all information required to certify airworthiness. Additionally, Box 12 is where to put statements and disclosures, including whether the form is a corrected version or if it is a dual release.

- Blocks 13 and 14: Either section 13 or 14 will have relevant information, depending on whether the form is for a new product or RTS purposes. Forms cannot be for both purposes simultaneously, so one column will always be blank. Either column will contain a certification of conformity or airworthiness, signatures from authorized authorities and the inspection date.

If you are unsure your form is correct, speak to the issuer or to your region’s FAA Field Office.

FAA 8130-3 Requirements

The 8130-3 airworthiness approval tag covers a highly specific list of requirements a product must meet, depending on its purpose. 14 CFR Part 21 covers the certification process for aviation products, giving FAA-approved assessors a guide for certification. While meeting 8130-3 requirements will vary depending on the product, here’s a brief outline of what manufacturers must follow.

- Compliance with FAA regulations: Products must meet all relevant FAA regulations. Each product must follow the approved manufacturing processes, material specifications and design standards.

- Quality control: The manufacturing process should use effective quality control procedures while manufacturing the product. Documented quality control standards demonstrate that components meet requirements.

- Component conformity: Each component must conform to approved design specifications. Serial numbers, part numbers and compliance statements should all meet these standards.

- Documentation: Documentation is critical throughout this process. Products must prove compliance with all applicable standards and regulations. These should always accompany the 8130-3, if approved.

- Authorized signature: An authorized person should always sign the 8130-3 form. Failure to get signatures from appropriate authorities means the product’s 8130-3 form is not valid.

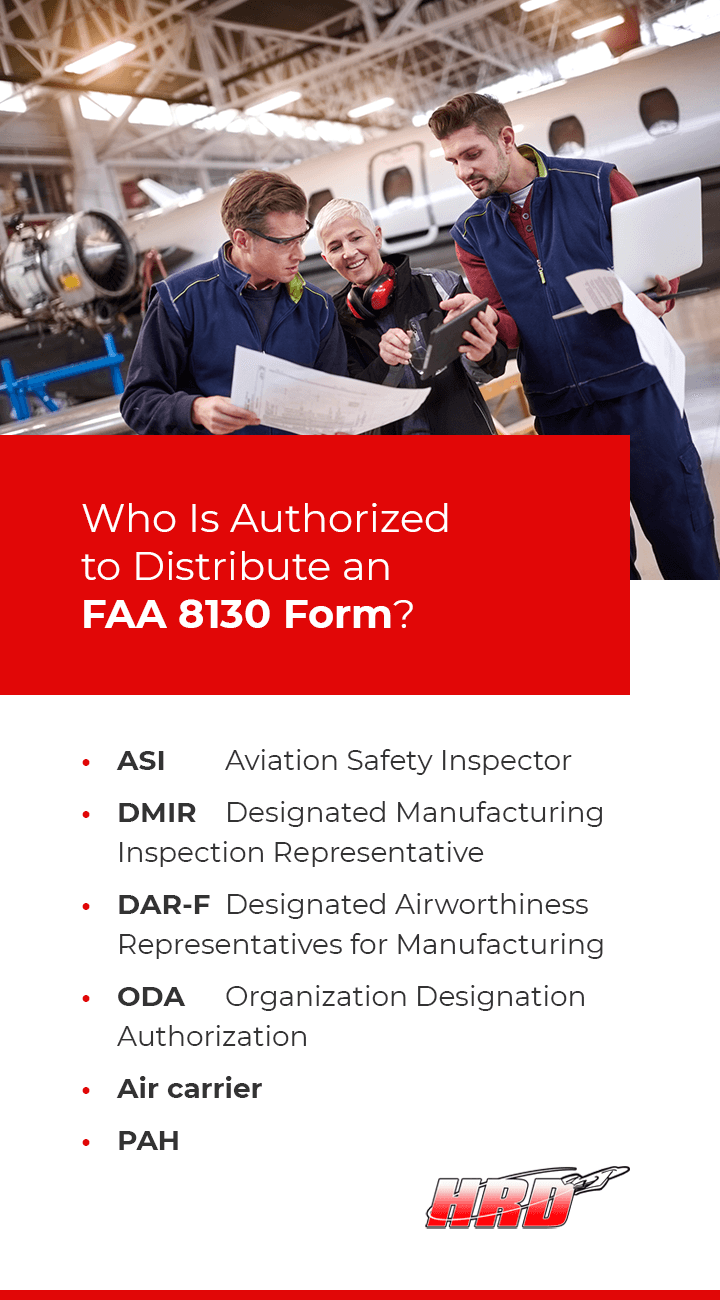

What Is the Difference Between CoC and 8130-3?

A Certificate of Conformity, or Statement of Conformity, is a page that proves an FAA-approved production process and company manufactured a plane or plane part. The FAA or an FAA representative gives you the CoC, while the 8130-3 comes from FAA-authorized carriers or certified repair stations.

The plane or part manufacturer must complete rigorous testing and quality assurance processes to get a CoC. These tests ensure the product meets FAA standards, ensuring it’s safe for flight. Tests might cover material testing, design validation, performance testing and more.

Once a product meets requirements, it receives the CoC. The purchaser and regulatory agencies will get to see this proof of compliance and move forward with the product. CoCs are essential for proving that a product meets all the safety checks needed for aviation use.

Repair Services From HRD Aero Systems

If you’re looking for professional aircraft component manufacturing and maintenance that offers the 8130 form, choose HRD Aero Systems. We deliver durable and efficient aircraft safety equipment. For over three decades, we’ve provided world-class services that are FAA, JAA and airline approved. We specialize in producing and overhauling critical safety equipment for aircraft, including aircraft fire extinguishers, oxygen equipment and survival equipment.

We hold an extensive stock of all our products, so we can quickly exchange or sell units for same-day shipment. As for our repair services, we maintain a three-day to five-day turnaround for routine services and 24-hour emergency maintenance. We have locations in Malaysia, Texas and California, so we are ready to serve you anytime, anywhere.

To learn more about HRD Aero Systems and our services, contact us today!