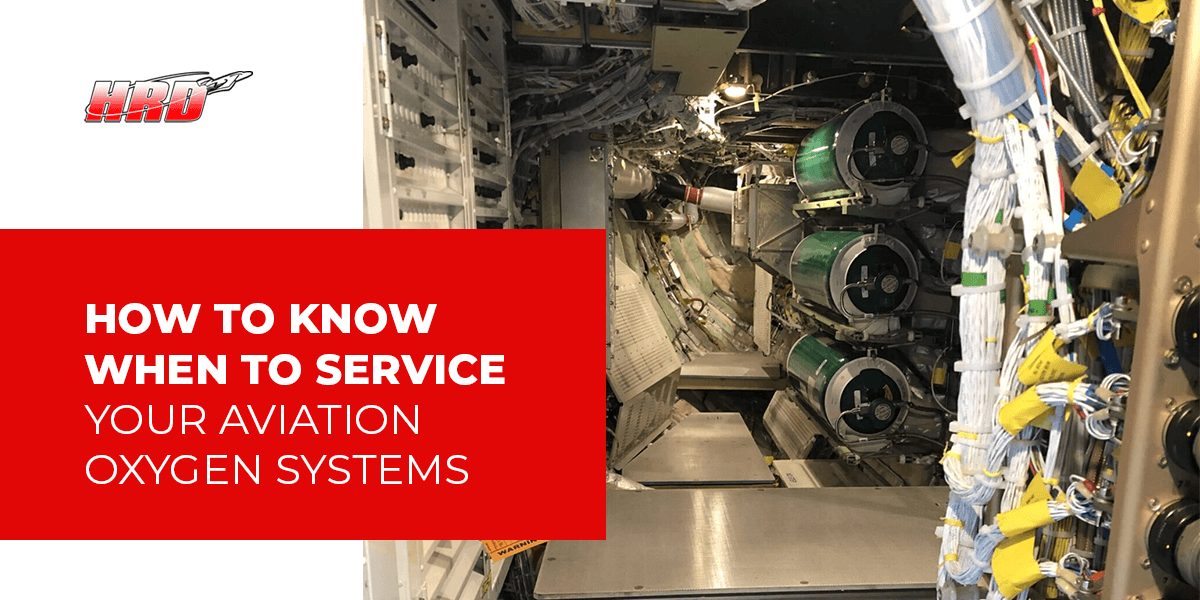

Oxygen systems require servicing to ensure aviation teams avoid potentially hazardous situations. Depending on the system you have, you can create comprehensive service schedules to ensure each component is functioning efficiently. Here’s what you need to know to create a service schedule.

Understand Your Oxygen System and Components

Whether you use a fixed or portable oxygen system, your system will utilize several fundamental components, including cylinders, valves, regulators and flow indicators. Depending on the cylinders you have, you can create a refined servicing schedule. You should test DOT 3AA cylinders every five years and DOT #HT cylinders every three years. Implement testing for composite cylinders every three years.

Best Practices for Servicing Your System

Servicing your oxygen systems requires several necessary actions. You must follow proper procedures for handling, cleaning and filling your oxygen systems:

- Cleaning: While specific cleaning requirements can vary, as a general rule, plan to clean your system annually. Always follow defined cleaning procedures. Look for signs of wear and tear or damage to your system during cleaning. Perform visual inspections on connections and hoses, and replace filters depending on environmental conditions and usage.

- Filling procedures: You must verify the purity and availability of system oxygen. Manufacturer guidelines and pressure gauges typically indicate when filling is necessary. Standard aircraft oxygen servicing procedures will confirm the equipment’s ability to meet regulatory standards before starting a service. The filling process requires a professional to purge any potential contaminants or clear residual gas from the cylinder before filling the components with breathing oxygen. Controlled filling with the appropriate amount of oxygen is critical. After completing the service, a repair station must document all processes and label the system with pertinent data, such as the fill date.

- Handling and inspection: Professionals must use proper safety techniques and handling procedures to maintain oxygen cylinder integrity and prevent damage. When inspecting the system, look for signs of leaks and evaluate all expiration dates. Implement proper storage practices for cylinders — keep them upright and secure them after moving.

Request Aircraft Oxygen System Servicing

HRD Aero Systems is your dedicated aerospace industry leader. Our team services safety equipment to ensure safety and quality. Our oxygen system services include system testing, refills, repairs and overhauls. With over 35 years of experience supporting customers from all aviation industries, you can feel confident in our ability to deliver reliable services you can trust. Contact us for comprehensive oxygen system services. We’re on board with you.